ISO, the International Organization for Standardization has developed a universal tire sizing system that eliminates this confusion. (This system was formerly known as the "E.T.R.T.O." system, developed by the European Tyre and Rim Technical Organisation.)

Download the following file for complete information!

| knowledge_about_rims.pdf | | File Size: | 151 kb | | File Type: | pdf |

Download File

Rims

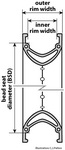

Older rims were made of steel, but steel rims are now obsolete, and only found on the cheapest, crummiest bicycles. Aluminum rims have superseded steel, because they are lighter, stronger, rust-proof and provide better braking. Modern rims are made of extruded aluminum, that is, the semi-molten aluminum is squeezed out of specially-shaped openings which determine the cross section of the rim. The extrusions are formed into hoops, then joined either by welding or by the insertion of a filler piece into the hollows of each end of the rim. Many good quality rims have "eyelets" or "ferrules" to reinforce the spoke holes. [Following paragraphs added by John Allen] A rim can get damaged by an impact with a pothole edge, rock, etc. Rim brakes wear down the sidewalls of aluminum rims, especially in wet-sandy conditions. Eventually, the air pressure in the tire can bulge a sidewall out, causing a blowout. You can usually just transfer the old spokes to a new rim, avoiding the need to relace the wheel -- see Jobst Brandt's article.

There has been a trend toward deeper-section rims in recent years, in the interest of ærodynamics. Moderately deep-section rims are spoked like any others. Extremely deep-section rims can work with somewhat fewer spokes than conventional rims. As few as 20 in a front wheel may be practical -- also an ærodynamic advantage. But there are important downsides. Extremely deep-section rims are excessively stiff, and must be very true as supplied, without coaxing from the fewer spokes. If the tire bottoms out on a rock or other obstacle, such a rim does not provide a "crush zone" to the same extent as a conventional rim. There is more likelihood of damage to the bicycle's fork and frame. The rim will probably crumple and be unrepairable, or if it is of carbon fiber, it will tear. These rims are heavier, too, all other things being equal. The strength of the tried-and true wheel design is in the spokes, not the rim. Where high ærodynamic efficiency is important, a better technical solution is a rim of the required strength and stiffness, with a lightweight wind fairing. In fact, triathletes and HPV racers have used wheels like this for many years. The hidebound rules of the U.C.I, on the other hand, prohibit any part of a racer's equipment from serving only an ærodynamic purpose. The result has been "Frankenstein" equipment such as deep-section rims and "æro" helmets whose long, protruding tail adds weight and can twist the rider's neck if he/she lands the wrong way. Pro racers put up with all this because any tiny speed advantage could win a race, and because the team pays for their equipment. Even less practical than wheels with very deep sections are wheels with unevenly-spaced spokes, or with spokes which attach to the rim and hub in unconventional ways and locations. Some of these wheels provide a real advantage to racers; others only a placebo effect. These wheels tend to be very expensive, and a real headache to repair or rebuild, because of the special parts and tools needed.

From: http://www.sheldonbrown.com/wheelbuild.html

Wheels consist of the following components: - The hub, containing an axle, the quick-release inside the axle, and two or more bearings holding the rotating hub body with the flanges that hold the spokes. The quick-release is an ``inner axle'' with a nut on one end and a lever on the other, and two conic springs that simplify installation. The small ends of the springs point to the center of the hub. The nut should be tightened such that closing the lever is hard but can be done with one hand (how is that for an imprecise unit of measurement :-) A loose quick release can cause the rear axle to shift in the dropouts when accelerating hard, causing the tire to rub, or in the worst case can work itself even looser until you are in danger of losing the entire wheel. There are two kinds of hubs, obsolete freewheel ones where the sprocket assembly contains the coasting bearings and ratchets that screws onto the hub itself, and cassette hubs where the bearings and ratchets are built into the hub and the sprockets are fixed. Do not under any circumstances use the former type; they contain a bearing that runs near the center of the hub that can bend the axle. The latter type has bearings on both ends where they can't bend the axle. A bent axle can bend or break the right dropout of the frame, and you'll have to write off the entire frame! It happened to me twice.

- There are usually 36 spokes. Some people prefer 32 for reasons that are not clear to me, or even 28. Tandems can benefit from 48 spokes. Staying with 36 spokes offers the widest selection of hubs and rims. There are double-butted spokes that are narrower in the middle where there is less load, bladed spokes, wavy spokes, and other exotica. Double-butted spokes make sense (spokes always break at the neck or where the threading begins), the rest is fairly useless. Bladed and wavy spokes are also more difficult to install because they twist and make it hard to gauge tension. Spoke thickness is usually measured in ``gauge''; smaller numbers indicate larger diameter. Spoke length is important, but computing the right length is a black art. Generally, all spokes of the front wheel have the same length. Sprocket-side (right) rear spokes are shorter, outer (left) rear spokes are slightly longer because the right rear hub flange is close to the center of the hub. When buying replacements bring an old spoke. Up to a millimeter too short doesn't hurt, but spokes that are too long can puncture the inner tube. Wheels can be built radial, 3-cross, and 4-cross. Radial means that spokes run straight to the rim without crossing; 3-cross and 4-cross refer to the number of times a spoke crosses other spokes. 3-cross is standard. There is no reason to use radial wheels except aesthetic reasons; it reduces the strength of the wheel and makes the ride rougher. Obviously, each of these spoke patterns requires a different spoke length. By the way, always use steel spokes and brass nipples.

- There are many types of rims: rectangular profiles (like Mavic MA-2 or Campagnolo Delta), aero profiles (like Campagnolo Omega), and anything in between. High-quality rims are machined to avoid the normal seam where the rim joins; this seam can catch the brake pads and cause uneven wear and braking behavior. Don't buy black-anodized rims; the anodization will be quickly worn away where the brake pads rub against it.

- I swear by Campagnolo rims. Mavic is ok, but look at their high-end double-butted rims - the holes are apparently punched, not drilled, and if you hold them just right you can see small discolorations where the metal was deformed. This weakens the rim, and just now (9/99) two spoke sockets were torn from my rim at such points, leaving huge holes. Campagnolo rims are drilled and finished perfectly. My current favorite is the Moskva 80, but they no longer make it.

- Inside the rim, rim tape protects the inner tube from the spoke ends. There are two types, adhesive textile tape and tough hard plastic. Both work equally well but the hard plastic is difficult to remove without tools while the textile tape may expose the inner tube to spoke holes if chosen too narrow. Reinstalling the hard plastic type can lead to mysterious flats because the tape lenghtens during removal, and when the tire is reinflated the tape may get pushed aside or into the spoke holes until the tube touches sharp metal edges of the rim. When you take it apart to find the reason for the puncture, it shifts back into place, hiding the problem. Use adhesive textile tape if possible. Aero rims are stiffer but are more difficult to install because spoke nipples have a tendency to get lost. Always use aluminum rims, steel rims brake dangerously poorly in wet weather despite brake pad manufacturers' claims. Make sure the rim does not just have spoke holes drilled into it but some kind of steel sleeve that protects the hole. Absolutely never buy an aluminum rim if there are discolorations on the outside around each spoke hole when held against the light. Discolorations indicate that the holes were punched rather than drilled; rims like that can fail abruptly when the hole cracks and spokes pull out. I have destroyed several Mavic MA2 rims that way when touring with bags.

- Inner tubes come in butyl and latex, in various weights. 100-gram butyl is best. 60-gram butyl is too vulnerable to snakebite punctures, and latex leaks air and can rip off the valve if the tire slips for any reason. Choose a valve stem that is threaded all the way to the tip without any smooth parts because pumps tend to hold poorly to smooth valve stems. There are two types of valves, Presta (French) or Schrader (like those used on cars). Presta valves are narrower and are always used for racing bicycles; Schrader valves are found on mountainbikes. Presta is easier to pump because one doesn't have to work against a spring. Don't forget to unscrew the nipple before pumping. The maximum pressure allowed depends on the tire; it is printed on the side of the tire. One bar is approximately 14 psi; road tires usually hold 8-9 bar. Don't underinflate because you are more vulnerable to snakebite punctures; don't overinflate because the tire can pull off the rim and cause nasty crashes if the loose tire edge gets caught in the brake. Don't buy a pump that inflates the tire with both in and out motions. You need to wait for the builtin valves to restore air pressure in the pump at both ends of the stroke, which takes several seconds so it takes forever to inflate the tire. It sounds like a good idea but you'll hate it after three seconds. The best frame pumps ever built are the aluminum Zefal X3 and X4 pumps; they have a cap that twists to lock the internal spring so that all the force put into it directly translates to tire pressure. Brilliant. Unfortunately few stores carry them.

- Tire liners are Kevlar belts that are inserted between the inner tube and the tire to prevent punctures by sharp objects. More on that below.

- Tires for road bikes should always be bald (smooth, untreaded). It may be counter-intuitive but they have higher traction. Fatter tires make for a smoother ride on rough roads or when touring loaded; narrow tires deform less and waste less energy. I prefer 20mm front and 23mm rear tires (but watch out, different manufacturers seem to rate their tires differently). There are Kevlar-beaded (foldable) and Kevlar-belted (puncture-proof) tires. Puncture-proof tires aren't, because the belt is too narrow. On the contrary, it seems to be hard to laminate smooth Kevlar to the outer rubber layer, I have had tires come apart. My latest trip to France (2001) saw two brand-new Vittoria tires with Kevlar belts come apart after a few days, which first pulled the tire into an S curve and then developed a fuzzy hole. I do not buy Vittoria tires anymore, and some shops have stopped selling them. Make sure the side wall is strong enough. My favorites are foldable non-belted Avocet road (not Criterium!) tires; they last practically forever and still have a rubber that is soft enough to afford traction on wet roads. Recommended. Too bad that they only make the wide versions anymore. These days I mostly use Continental tires; a little heavy but very robust.

Preventing Punctures Inner tubes puncture for two reasons: either a sharp object penetrated the tire or worked its way between tube and tire, or the wheel "bottomed out" and the tube got pinched between rim and tire. The latter usually causes a pair of telltale "snakebite" punctures. Punctures caused by sharp objects such as nails, wires broken off from street-cleaning machines, and glass can almost always be prevented with a Kevlar tire liner. At this point I used to recommend ``Mr. Tuffy's'', but recent experiences have shown that they cause way more flats than they prevent because the hard edges rub against the tube until it blows out. No amount of sanding and melting with a lighter has fixed this. They used to have a soft version that worked well, but the current version, recognizable by the black stripe, is dangerous. Don't buy! If you must use them, cut the end straight off and only soften the corners a bit; don't cut a long soft curve because it's the sides that eat into the tube. There is a ``green slime'' brand that spares the tube, but it's a little on the soft side and lets some debris pass, and only lasts a year or two before it falls to pieces. Still seems to be the best bet right now (2004). Snakebites are caused when hitting an obstacle such as a pothole hard so the inner tube gets pinched between the rim and the obstacle. Tire liners help very little here. The best prevention is to inflate the tube to exactly the pressure printed on the side of the tire at all times, and rechecking the pressure at least every other week because butyl inner tubes leak air. Latex tubes are nearly puncture-proof but leak air at a frightening rate. Do not use light-weight tubes. Some of them weigh 60 grams or less, but are very prone to punctures. If you use tire liners, occasionally check for pieces of glass that became lodged in the tire; they can work their way into the tire if left in long enough. Look as if you knew what you are doing when cutting away at your tire with a knife point. Do not use ``Wrench Force'' tubes, they have inferior valves that break easily when installing. Repairing Punctures You need two plastic tire levers, a pump, and either a repair kit or a new inner tube. Let all air out of the tube and push the tire towards the center, away from the rim, all around the wheel. Insert the spoon-shaped part of one tire lever between the rim and the tire at the place where you suspect the puncture, scoop the tire out of the rim, and hook the other end into a spoke. Very carefully insert the spoon end of the lever only as far as needed to prevent pinching the tube. Repeat two spoke holes away from the first with the other lever. Repeat until you can pull the tube out of the tire. If you are on the road and have a spare tube, it is usually best to install it and fix the punctured tube at home, in a warm and dry place. This requires removing the wheel by releasing the quick-release lever in the axle. In the case of the rear wheel, shift to the smallest rear sprocket first. Mountainbikes sometimes require unscrewing the quick-release nut partway because of ridges in the dropout that prevent accidentally losing a wheel when the quick-release comes loose. Small holes can be fixed by glueing a patch. I have never managed to reliably patch a hole more than a millimeter or two in length. If the hole is large, an air bubble will form under the patch and find a way out. Snakebites require a large patch that covers both holes. Pump up the tube to find the hole. Let nearly all the air out of the tube again, clean and dry the tube around the hole, and use the sandpaper to roughen the area. File off seam protrusions. Apply a thin coat of glue that is larger than the patch. Patiently wait until it dries, which takes a couple of minutes (impatience is rewarded with a patch that comes loose soon). Apply the patch and press on hard at the center and all around the edges. Continental patches seem to be the best. Always push the air out of the glue tube when replacing the cap so it won't dry up quickly. To reinstall the tube, inflate it so it just barely holds its shape. Insert the valve and push the tube into the tire there. Working away from the valve, push the tube into the tire while slightly pushing it towards the valve. Alternatingly work from the left and right of the valve to prevent the valve from being pulled in one direction. If the tube is so long that a loop remains after it is fully installed, don't squeeze it in but pull it all the way out again and retry, this time pushing it harder towards the valve. The goal is to keep the tension of the tube constant along the circumference of the wheel. It's easier than it sounds. If you have a tire liner, always keep it centered, and place the overlap of the liner ends at the side opposite from the valve. Push the open end of the tire into the rim beginning at the valve, taking special care that the tube is not trapped between rim and tire, and work away from the valve. Usually it is hard to push in the last bit on the opposite side. First try pushing the tire towards the center of the rim while pulling it towards the remaining loop. If this is not sufficient, let all air out of the tire. If all this fails (and only then), you need the tire levers again. Put a little bit of air into the tube so it holds its round shape and insert the spoon-shaped end of a tire lever between tire and rim, but with the "wrong" side up - not hooking into the rim but with the inner side of the curve towards the tire. This makes it harder to push the tire in but reduces the risk of pinching the tube. Begin near the ends and work towards the middle of the section not yet pushed in. You can use the hook end of the other lever to keep the tire from pushing out of the rim at the other end. Sometimes the wall of the tire gets punctured. This is dangerous because the tube will form a bubble there that can explode with a loud bang. Torn tire walls are unfixable but you can keep the tube inside by inserting a folded dollar bill or some other denomination of your choice. Paper money is incredibly strong and will last years if the hole is not too large. If the threads in the side wall are damaged so much that the tire bends out of shape after inflating, it's unfixable, you need a new tire. Obviously, don't do dangerous downhills with such a fix, it will probably fail at the worst possible moment. Fixing a Rubbing Wheel If your rim rubs against the brake pads in a few places, the wheel needs to be retrued. This can be done safely only if the rim is undamaged; if it was bent, for example by bottoming out on a curb, the procedure still works if the damage isn't too great but it won't last long - spokes may snap or unscrew. I am assuming that you are using aluminum rims. If you have steel rims the procedure is the same but takes much longer because not only the spokes near the rubbing spot are involved but all other spokes too. First, use chalk to mark the range that is rubbing. In that range, either loosen the spokes on the rubbing side or tighten the spokes on the other side. Compare the tension of the spokes in that area to the tension of spokes elsewhere to decide which of the two is right; if you can't feel a difference do both. Use a spoke wrench to adjust all spokes in the rubbing area; the ones in the center of more than the ones where the rubbing area begins and ends. Never turn the nipple more than one quarter turn at a time. If in doubt whether to tighten one side or loosening the other, go for tightening because slack spokes can unscrew all the way while riding. After adjusting, grab every crossing pair of spokes on both sides with your hand and pull them together hard (this releases tensions built when spokes are twisted). Test whether the rubbing spot got smaller, and repeat the procedure until the problem is gone. There is usually no point in tuning the wheel better than one millimeter, that is, to less than a sideways wobble of 1mm relative to the brake pads. It often helps to move the brake pads closer together than normal to identify wobbles. Replacing a Rim Bicycle wheels need to be properly adjusted for smooth riding and to prevent the rim from rubbing against the brake pads. The most common cause for misadjusted wheels are accidents and lack of maintenance. A rim with a dent or other damage is practically impossible to realign; any attempt to do so by pulling it back into shape will cause broken spokes, or spokes that continuously unscrew and go slack. Replacing a rim is much easier than building a wheel from scratch. Buy a new rim with the same number of holes and the same inner diameter. The inner diameter is smaller for some "aero" rims. Avoid black-anodized rims because the anodizing will rub off after a while. Always use aluminum rims, never use steel. Steel is hard to true and brakes poorly even with special brake pads. Place the old wheel flat on a table and tape the new rim to the old one, making sure that the valve holes line up. Also make sure that the spoke hole pattern lines up if the holes are alternatingly offset left and right from the center. Next, loosen all old nipples but do not completely unscrew any of them. Beginning with the spokes ending at the flange facing up, unscrew the nipple and move the spoke to the new rim, one at a time. A few turns of the nipple suffice. Apply a small amount of grease to the threads before screwing on the nipple. Continue with the remaining spokes until none are attached to the old rim, which you can now remove. The wheel will be very floppy at this stage. To avoid losing nipples in the rim, screw the wrong side one turn into a spare spoke, which you can then use as a handle. If the old rim was built with the correct spoke lengths (which are different on the left and right side for the rear wheel), the threading of the spokes was completely covered by the nipples. Now carefully tighten all the nipples until the threading is just barely hidden. This must be done carefully because it ensures lateral trueness. All spokes will still be rather loose after this. I use a power screwdriver. Next, beginning at the valve, tighten every nipple with a spoke wrench by one half-turn, in sequence, until you reach the valve hole again. Repeat until all spokes feel about as tight as they were in the original wheel. For rear wheels, tighten the spokes on the sprocket side much more than the ones on the outer side to keep the rim in the center. This sort of happens automatically with the above method because the sprocket-side spokes are shorter than the outer ones, but it helps to complete the sprocket side before beginning with the outer side. Get a feel for the spoke tension before taking apart the old wheel. The wheel is now tight but not true. Install it on the bicycle and turn the wheel to see where it rubs against a brake pad. If it does not turn at all or rubs in too many places, loosen the brake cable so that the brake pads move away from the rim. In places where the brake pads rub, tighten the opposite spoke until it no longer rubs. Always tighten neighboring spokes too. Never tighten a nipple by more than a quarter-turn at a time before rechecking. If a spoke seems to become much tighter than its neighbors, loosen the spokes on the opposite side (i.e. ending at the hub flange on the rubbing side) instead of further tightening. When the rim no longer rubs against the brake pads, move the brake pads closer together and repeat, until there is about one millimeter between the pads and the rim on either side, on average. During trueing, periodically pull every pair of neighboring spokes on one side together as hard as possible with one hand. This releases tension that builds up in the spokes during trueing because tightening nipples also twists the spoke. It may help to pluck spokes and comparing the pitch of the sound, but I find this method hard to use and inaccurate. After the wheel is finished, reinstall the rim tape, the tire, and the tube, inflate, and ride around the block a few times, then recheck the wheel by releasing tension again and checking trueness. Traditionally, tires are mounted such that the label is at the valve on the right (chain) side of the bicycle.

Source from: http://www.bitrot.de/bbook_wheels.html

I will never imagin that my post on Tarkbike brings such hot discuss, agreement and disagreement are posted there back and forth, maybe you can join us! click below link to come in!

Tittle as: Unkowned rim brand, posted here! *Best thread ever, everyone must read

We finally decide to define our brand as EroWiT, since our hope drives us to do so, that is, we want to bring health and green life style to our users and provide high performance but super light rim for use. And the brand, we define as ZERO WEIGHT, this is also the meaning it comes to being.

Moreover, the reason why we'd like to establish our brand at the first time is based on the reality that China has been the factory of the world, provides cheap but quality products for global users, but rarely has self owned brand to compete in the world market using its own brand name, and just gain little out from lion's share. Now is the time for us to establish our brand to take the lion's share, long time we know but it is the way start here!

|

RSS Feed

RSS Feed